The Technology Behind Flexible Shafts

Explore the engineering that powers reliable torque transfer in multiple applications, from industrial machinery over air craft to medical devices.

What are Flexible Shafts?

Core Engineering Strengths

Every BIAX flexible shaft is built with quality, performance, and durability in mind. These key attributes define our engineering approach and ensure dependable results across industries and applications.

Adaptability

Works in complex scenarios.

Durability

Withstands harsh environments.

Customizable

Tailored to fit specific needs.

Precision

Smooth, reliable torque transfer.

Versatility

Supports high speeds and torques.

Top Functional Benefits

BIAX flexible shafts solve mechanical challenges that rigid components can’t. From navigating blocked paths to absorbing vibration and shock, these benefits highlight how our shafts enable motion in the most complex applications.

Dampen Vibration

Reduces vibration from drive systems to protect sensitive components.

Moving Positions

Maintains function while connected components shift or move.

Harsh Environment

Performs reliably in extreme temperatures, dust, or moisture.

Absorb Shock

Minimizes mechanical shock and load spikes in critical systems.

Shaft Core Types

BIAX offers a variety of shaft cores tailored to meet the needs of diverse applications. From low-torsion solutions to high-speed designs, each core is engineered for durability, flexibility, and reliable performance in demanding environments.

Low Torsion

Ideal for manual operation or low-speed tasks requiring high torque and a low torsion.

Universal

Good torque transmitting on medium RPM applications with small bending radius.

High speed

Extremely flexible with a small bending radius for high speeds up to 50.000 RPM.

Stainless

Specially designed for medical or foodstuff applications

Hollow Shafts / Helices

Offer space to route cables, wires, fibers and hoses inside for medical and technical applications

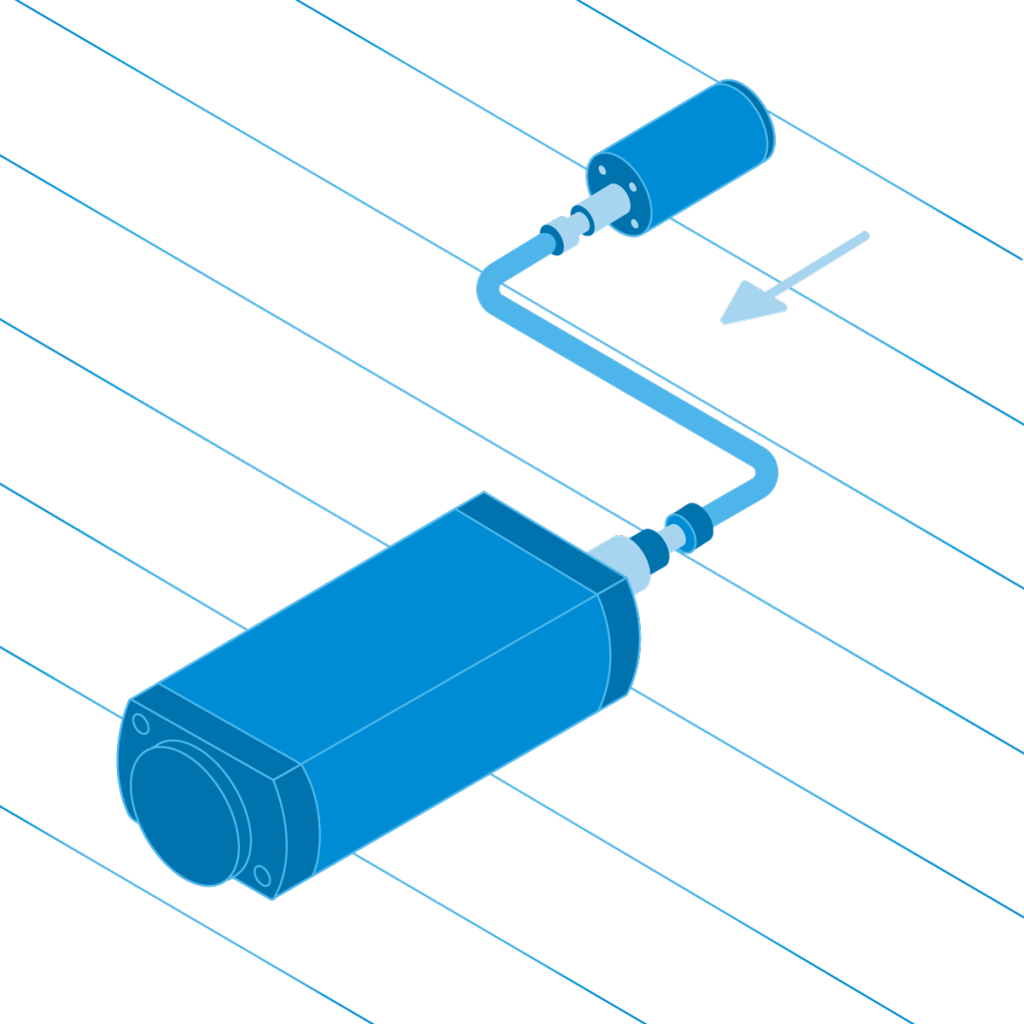

BIAX Connections

Protection Hoses

Common Applications

Flexible shafts are versatile components solving unique challenges across various technical applications.

Ask UsDriving a machine

Our flexible shafts transmit uniform rotary motion from a motor to a shaft, ensuring reliable performance in brush cutters, gearboxes, conveyor belts, and grinding or milling machines.

Adjusting a machine part

Emergency actuation

Special applications

Extreme environmental conditions

Ready for Flexible Shafts?